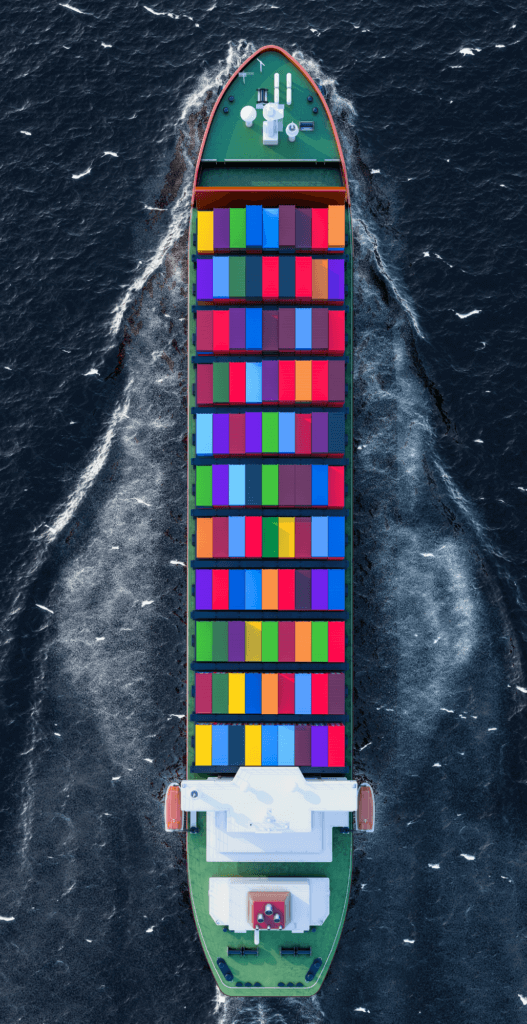

Your product leaves your warehouse in pristine condition. When product damage occurs during transit your business suffers: costly losses with replacements and their transit, refunds, and damage to the quality perception of your product and the reputation of your brand. BoldtSmith’s comprehensive experience with package testing services will help your company minimize the risk of damage and maximize your product protection.

Package testing is used by our expert engineers to evaluate the durability and protective capabilities of your packaging designs and shipping materials. We subject packaging to various tests and simulations that replicate real-world shipping conditions, such as drop testing, vibration testing, compressions, and environmental conditions.

Package testing enables us to identify the weaknesses and vulnerabilities in your current packaging that may be leading to product damage all along the transit journey. This provides us with valuable data that will guide informed decisions on how to reduce the risk of damage efficiently and effectively.

At BoldtSmith, our clients turn to us to manage the testing process from start to finish. While we’re not the testing lab, we determine which tests are right for our clients, prep the necessary materials for testing, and, most importantly, interpret the data to develop custom solutions for our client’s needs.

A big part of the package testing puzzle is identifying which testing standards make sense for your business. Not all packaging materials or designs can be tested by the same method. Our team knows which specific tests work for you business’ needs in order to minimize product damage.

ASTM International, formerly known as American Society for Testing and Materials, is mainly used for distribution testing with a focus on testing the materials used within packaging systems. ASTM is one of the first sets of testing standards that others have developed from. ASTM standards involve performance testing of shipping containers and systems, which includes vibration, drop, shock, compression, and atmospheric conditioning tests, all of which assess the ability of packaging to withstand the rigors of distribution.

The International Safe Transit Association (ISTA) offers a series of package testing procedures designed to evaluate the performance of your packaging and shipping. This standard specifies requirements for packaging and addresses packaging system validation through performance testing and documentation. E-commerce platforms like Amazon favor ISTA standards and oftentimes require it in order to sell to their customers.

BoldtSmith can help you achieve testing certifications. We begin with a thorough evaluation of your current packaging materials and designs, as they perform in transit, to create a baseline performance measurement.

We use third-party testing labs to ensure you get unbiased results. To do so, we identify and initiate the correct testing to see if your packaging solutions can withstand various drop tests, vibration tests, compression tests, and more. We take the data from these tests coupled with our experience in industry standards and procedures to customize your packaging solution. We can do this all while creating packaging and shipping solutions that help your bottom line.

Don’t get in the weeds with which testing standards are right for your needs. Let us do the heavy lifting.