Colton was very thorough in taking the data during our packaging trials and also aligning the team members on next steps during the fluid nature of each trial.

We don’t manufacture materials, make boxes, or sell crates. We are a team of packaging consultants and engineers who design and optimize product packaging for sustainability and cost reduction.

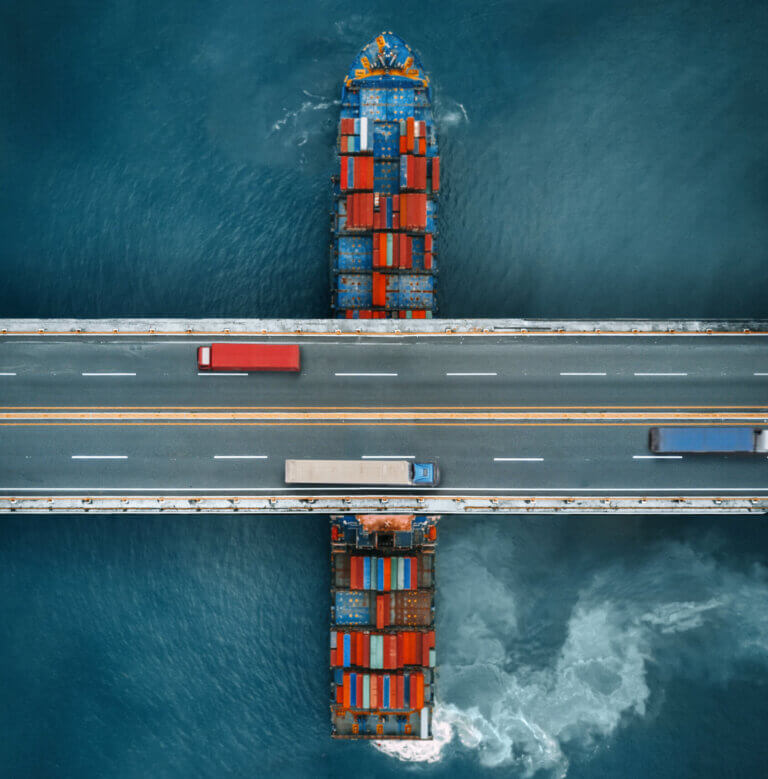

Whether it’s lightbulbs or turbine engines, juice drinks or windows, we go deep into possible solutions and “run the numbers” on the ROI of each. We engineer designs for sustainability, fix packaging system inefficiencies, and work with clients around the world as their go-to “in-house” packaging experts.

The fastest way to uncover profit and support product quality is with optimized packaging. BoldtSmith’s team of packaging consultants and engineers are experienced across multiple sectors and are impartial to materials and vendors, giving us the broadest solution set in the packaging industry. We’re driven by data and respectful of user experience.

Every day, our customers trust us with their brands and their business, and we don’t take that lightly. In the process, we set the industry standards for comprehensive packaging consulting services and cost-effective packaging solutions.

There are many components to an ROI calculation: materials costs, damaged product costs, assembly costs, and manufacturing slowdowns when you don’t have what you need when you need it.

What if changing the way you package products could add millions of dollars to your overall profit calculation? Our packaging consultant services have delivered this level of cost reduction. By optimizing packaging for efficient transportation and by reducing damaged product rates, our solutions go beyond just making materials cheaper.

In fact, they may involve better materials and improved presentation.It is likely that you have untapped profit that can be recovered simply by changing the way you package and protect products. Need immediate savings? Our packaging engineers have got your back.

Our packaging consultants assess products for vulnerabilities at the source of packaging. We follow the product’s path through every stop in the supply chain.

If products have a chance to be dropped or handled roughly, we simulate those conditions over and over. By leveraging risk analysis, we identify and implement structural design improvements that prevent damage and ensure durability.

Making sure a product arrives safely—large, fragile, liquid, cold, or in 100 disassembled parts—requires the closest look possible at what it’s up against every step of the way.

Return on investment, which is net savings and increased profit over time, is everyone’s goal. There is a lot of talk about sustainability and reduction in carbon goals as well. Those two goals are not mutually exclusive.

NET GREEN™ is how we evaluate changes in packaging systems and packaging design for measurable sustainability improvements. It is data-driven and quantifiable, ensuring your efforts lead to real impact.

Focusing on ROI and saving money by optimizing packaging solutions is, in fact, the most sustainable thing you can do regardless of where your company is in the supply chain. We provide you with the data to prove it.

Every packaging challenge is different. What you’ll see in our case studies reflects our problem-solving capabilities. Because we work in multiple sectors, such as CPG, medical products, OEM, military, and e-commerce, our packaging consultants apply insights differently than in-house teams. Efficiency is our guiding light, NET GREEN™ sustainability is the outcome, and undiscovered profit is the benefit we deliver to our clients.

We know it’s an old adage, but it drives our mission and truly is the yin/yang of our business: “Design to optimize. Optimize to save.” Packaging that is not optimized is a waste of money and a barrier to sustainability.

You’ll see our packaging consultants obsessing over details to impact the big picture: profit in reducing materials, profit in optimizing packaging systems, profit in minimizing product damage. This means increased profitability because our work delivers on NET GREEN™ sustainability.

Saving money and sustainability live in everything we do for our clients.

Our most commonly asked questions, optimized for your convenience

As packaging engineers, it’s our job to dive into the details. As your packaging consultant, we will look at a number of variables and key opportunities to help you optimize packaging efficiency, such as:

We kick off every project with a stakeholder meeting to ensure alignment with your goals. Our packaging engineers then explore multiple structural design iterations for consideration. Throughout the project, we share progress weekly, including sampling and testing. Every material specification is documented, ensuring clients own the data for long-term optimization.

Many businesses wonder whether hiring an in-house packaging engineer is a better option. The reality is that working with comprehensive packaging consulting services like BoldtSmith offers flexibility, scalability, and deeper industry expertise without the overhead costs of a full-time hire.

We work fast and have been known to start projects within days of your call. Our resources are free of the corporate distractions of running a business, allowing our engineers to focus 100% of their energy on solving your problem. Concepts are typically shared within 2 weeks of starting the project, and sampling follows immediately after selected concepts are finalized.

A site assessment allows our packaging consultants to examine and identify the largest ROI opportunities in your operation. We take a strategic analysis approach to assessing spend, design efficiency, labor costs, and the true cost of product damage. Our audits uncover savings opportunities that others miss.

As independent packaging consultants, we recognize that you may not have time to gather extensive data. While information on spend, damage claims, and supply chain logistics is helpful, it is not required. We structure projects to require minimal client involvement beyond regular check-ins.

Can’t find what you’re looking for? Call us +1 262-203-9522 or get in touch.

We’ve helped single companies save millions of dollars.

Here’s what our clients have to say.

Colton was very thorough in taking the data during our packaging trials and also aligning the team members on next steps during the fluid nature of each trial.

BoldtSmith Packaging was able to solve all of our packaging issues within the tight deadlines that we gave them. BoldtSmith Packaging gave updates daily on progress and drop test results. The final presentation for each packaging solution completed was much appreciated.

It was excellent working with Dave Branson throughout the project process. It was a very informative professional analysis of our problem. We had regular calls and the project deliverables were completed as promised.

Dustin was very knowledgeable and thorough. We very much appreciated his professionalism and insights throughout the on site assessment

The experience developing the retail packaging for Sausage Strips was painless and I had complete confidence in the successful launch of our newest product.

BoldtSmith has been a great partner throughout the design process. They are extremely responsive to their customers’ needs. This was critical to keep our project on schedule.

When I first started looking into getting help with our packaging I had no clue what a packaging Engineer was. Now I do. They were very professional and informative. The knowledge Aaaron had in packaging was incredible. The entire process was very interesting. It has benefited our company completely!

Recently worked with John Boldt at BoldtSmith on a design project. Couldn’t be more satisfied with the process and results! I will definitely recommend BoldtSmith and will not hesitate to work with them in the future.

Our goal was to get from failing ISTA 3 to passing ISTA 6A. The proposed package does that and is more compact. What was to be only a packaging improvement has become a huge DTV for us due to the 25% more per pallet. Some of the M-Can production is moving to our Mexico facility. The shipping savings will be in the 100’s of thousands.

BoldtSmith Packaging was a huge help to my company and assisted in securing multiple continuous improvement projects and realizing cost savings for my team.

Our organization needed to reduce quality complaints due to shipping. Great staff and were easy to work with, very diligent with on time task completion! Very agreeable team, efficient and knowledgeable. 10-10 recommend!

This was my first time working with BoldtSmith and the entire experience was very positive. The team reacted to an emergency need and performed quickly and efficiently to resolve our shipping container needs. We will certainly bring more work to them in the future.

BoldtSmith did a good job executing on the assessment phase of the project. Very responsive and communicative. Attentive to needs, changes. Reliable. Dustin did a good job leading the work.

Our project went very well right from the beginning. The project itself required a lot of attention to detail due to the packaging and protection requirements that were necessary. I worked with Max from their team and he did a fantastic job executing on all levels. All of the work was done in a timely, professional and satisfactory manner. I would highly recommend their design and consulting services!

BoldtSmith did a good job executing on the assessment phase of the project. Very responsive and communicative. Attentive to needs, changes. Reliable. Dustin did a good job leading the work.

BoldtSmith Packaging went above and beyond expectations with managing this program even though the end customer kept changing requirements. Very easy to work with and high level industry knowledge. Jack Ader was beneficial in providing several options and ultimately guiding the program to the right solution.

Our overall experience with BoldtSmith went extremely well. Max went the extra mile to make sure we got what we needed with tight deadlines. Max is the man!

We had a great experience working with BoldtSmith Packaging on this project. The project team adapted well to some changes and provided us everything we needed. Communication was great through this entire project. We had weekly meetings and were notified if anything changed with the packaging design. The Winston Team appreciates all the help and would gladly send a recommendation for BoldtSmith Packaging.

Working with BoldtSmith has been a real pleasure. Their knowledge and expertise are second to none. They brought our ideas to life and found solutions for our costly and inefficient process. John’s expertise in corrugated displays was critical in the design phase. He guided us to optimal savings and reduced our individual component inventory while keeping structural integrity top of mind. Extremely helpful and always hands-on from conception through to delivery. We will continue to trust in them for future projects.

Dustin is a knowledgeable, innovative, self-starter with a positive professional attitude. His ideas/design contributions and ability to work with our suppliers and top customers was a true testament to his wide-ranging skillset. He implemented cost-effective packaging, listened to all requests for changes, and was able to communicate every step of the process; this encompasses his true character and interpersonal skills. I highly recommend his services for any packaging-related project and will continue to work with him.

BoldtSmith Packaging was a pleasure to work with. We needed a packaging consultant for a project on short notice, and they were able to deliver. The team was clear about their capabilities and how we’d integrate with our internal teams and manufacturers. We’d appreciated their timely status updates and open communication.

Five figures spent with the BoldtSmith Packaging team has in turn saved our business six figures.

Going on seven!

Your team delivered well beyond our expectation on the cost saving goal, and the ISTA testing provides our customers with confidence that the product will arrive in good condition. The process was very easy and all of the objectives were met. Dave answered all of our questions in a timely manner and did an excellent job addressing concerns.

We selected BoldtSmith as a partner because they not only helped us find the best solution, they helped us show our industry you can find both cost-reduction and sustainability solutions. Working with BoldtSmith really opened our eyes. All of the data they were able to show us through their methodology was astonishing. And they were able to translate that data into a smart solution that really made it an easy decision.

The [BoldtSmith] team was knowledgeable and flexible. The process was well defined. The expectations were clear and the deliverables were always in focus and communicated well. [They provided] very important packaging industry and process knowledge that most internal teams do not have. I expect ROI in multiple areas.

The attention to details, the smooth communication, adherence to timelines and presentation of information all met the mark for us. Based on the results of this project, we engaged Boldtsmith for a 2nd project which was completed recently.

BoldtSmith gave 110% towards this project and even identified additional opportunities for improvement beyond this phase. We were absolutely pleased with the communication and quality of work – overall it was a great experience.

Dustin and his team bring the same enthusiasm and interest to packaging that we bring to livestock production. As farmers, we never focused on finding big savings in packaging – we always treated it as a necessary part of doing business. Luckily, Dustin and his team helped us find thousands of dollars in better boxes. In addition to the financial savings, our packing employees are grateful for the efficiencies Dustin’s team recommended – boxes are easier to load, we can now fit more on each pallet, and they cost us less than they ever have. Everyone wins!

Justin is technically strong and brought himself up to speed on packaging projects/process with limited guidance. He is agile and did a good job with navigating complex packaging initiatives ( Innovation and Renovation). His prior experience with aseptic packaging/processing was a huge plus.

The biggest reason that we choose BoldtSmith was the fact that they were willing to help design new packaging without actually selling packaging materials. This allowed us to keep our long-standing relationship with our packaging supply company while still utilizing BoldtSmith to improve the overall design.

Ultimately our ROI is customer satisfaction. Having a high-quality package for our equipment was a key to winning this business. From a cost standpoint, we may have got to an acceptable solution using internal resources as a lesser cost, but likely not have met the deadline.

Interested in seeing some of our work? Check out our case studies.